From farm to table, the dairy industry relies on top-quality cold chain solutions to navigate its complex supply chains. With dairy staples like milk, cheese, and butter being household essentials, the industry’s rapid growth is evident. In 2024, the Dairy Products & Eggs market sees revenue reaching US$1,170.00bn, with an expected annual growth rate of 7.32%. To meet rising consumer demand, superior cold chain solutions are essential for ensuring product freshness and safety. In response, a leading Bulgarian trading company that distributes milk products has entrusted to Loren Networks, and ELA Innovation for remote monitoring and real-time control of temperature in the range from -20 to +90°C. Their objectives were to include providing milk processing machines and cold storage chambers with remote measurement to optimize production processes, predict anomalies, and ensure cost efficiency through remote monitoring and proactive interventions. Around 40 ELA Innovation Bluetooth sensors, such as Blue PUCK T EN12830, Blue PUCK T-PROBE were deployed to achieve these goals in the temperature monitoring solution.

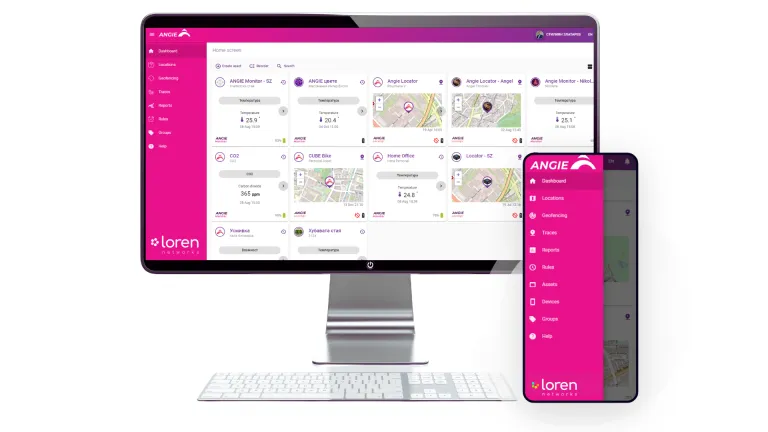

The end user expressed immense satisfaction with the IoT solution. The company highlighted how seamlessly management now accesses crucial data remotely via a user-friendly IoT app. Furthermore, the company’s technologists find great value in monitoring the production process in real-time, enhancing efficiency and decisionmaking. Thanks to the automation of weekly reports, once a time consuming task, staff commitments have been reorganized, freeing up valuable time. Moreover, thepredictive capabilities of the solution, leveraging historical data, enable proactive event management, further solidifying the company’s confidence in its operations.

Ivan Damyanov

Product Manager

From farm to table, the dairy industry relies on top-quality cold chain solutions to navigate its complex supply chains. With dairy staples like milk, cheese, and butter being household essentials, the industry’s rapid growth is evident. In 2024, the Dairy Products & Eggs market sees revenue reaching US$1,170.00bn, with an expected annual growth rate of 7.32%. To meet rising consumer demand, superior cold chain solutions are essential for ensuring product freshness and safety. In response, a leading Bulgarian trading company that distributes milk products has entrusted to Loren Networks, and ELA Innovation for remote monitoring and real-time control of temperature in the range from -20 to +90°C. Their objectives were to include providing milk processing machines and cold storage chambers with remote measurement to optimize production processes, predict anomalies, and ensure cost efficiency through remote monitoring and proactive interventions. Around 40 ELA Innovation Bluetooth sensors, such as Blue PUCK T EN12830, Blue PUCK T-PROBE were deployed to achieve these goals in the temperature monitoring solution.

The end user expressed immense satisfaction with the IoT solution. The company highlighted how seamlessly management now accesses crucial data remotely via a user-friendly IoT app. Furthermore, the company’s technologists find great value in monitoring the production process in real-time, enhancing efficiency and decisionmaking. Thanks to the automation of weekly reports, once a time consuming task, staff commitments have been reorganized, freeing up valuable time. Moreover, thepredictive capabilities of the solution, leveraging historical data, enable proactive event management, further solidifying the company’s confidence in its operations.

Ivan Damyanov

Product Manager

The project's participants

- The client's needs

- Technical Operation

- Results

The client's needs

✓ To receive notifications for any temperature changes that occur outside the production range

✓ To analyze the parameters of the production process for a certain period of time

✓ To predict potential problems and damages

✓ To analyze the parameters of the production process for a certain period of time

✓ To predict potential problems and damages

Technical Operation

From a technical point of view, the project operates through a sophisticated network comprising 9

GSM hubs and 36 Blue PUCK T EN12830 and Blue PUCK T-PROBE Bluetooth temperature sensors.

These sensors, featuring durable probes, autonomously measure temperature in extreme conditions,

boasting a remarkable battery life. The GSM hubs ensure seamless data collection and monitor power

supply, backed by backup batteries providing an hour of uninterrupted service. This setup empowers

the customer to streamline production processes, anticipate anomalies, and enhance cost efficiency

through remote monitoring and proactive interventions.

Loren Network’s IoT solution seamlessly integrates temperature sensors with certified probes via

Bluetooth to their central GSM hubs, enabling real-time data collection across diverse environments.

These hubs continuously monitor sensor data and external power supply status, with backup batteries

ensuring uninterrupted operation. Through remote access, anomalies are promptly identified and

addressed, facilitating optimized production processes. The end-user is able to visualize the history

of the variations in the form of graphs and reports on the Angie IoT platform.

GSM hubs and 36 Blue PUCK T EN12830 and Blue PUCK T-PROBE Bluetooth temperature sensors.

These sensors, featuring durable probes, autonomously measure temperature in extreme conditions,

boasting a remarkable battery life. The GSM hubs ensure seamless data collection and monitor power

supply, backed by backup batteries providing an hour of uninterrupted service. This setup empowers

the customer to streamline production processes, anticipate anomalies, and enhance cost efficiency

through remote monitoring and proactive interventions.

Loren Network’s IoT solution seamlessly integrates temperature sensors with certified probes via

Bluetooth to their central GSM hubs, enabling real-time data collection across diverse environments.

These hubs continuously monitor sensor data and external power supply status, with backup batteries

ensuring uninterrupted operation. Through remote access, anomalies are promptly identified and

addressed, facilitating optimized production processes. The end-user is able to visualize the history

of the variations in the form of graphs and reports on the Angie IoT platform.

Results

✓ Enhanced product quality

✓ Operational efficiency and predictive analytics-driven optimization

✓ Compliance with regulatory standards ensured and data-driven insights

✓ Increased throughput & waste reduction

✓ Operational efficiency and predictive analytics-driven optimization

✓ Compliance with regulatory standards ensured and data-driven insights

✓ Increased throughput & waste reduction

Equipment

- The benefits

- Results

The benefits

✓Set threshold technology levels for monitoring

✓ Receive notifications for temperature changes outside production range

✓ Enhance production processes by reducing human error

✓ Utilize a dedicated mobile application for continuous asset access

✓ Generate detailed temperature datasheets and reports access historical database

✓ Analyze production process parameters to predict potential issues

✓ Receive notifications for temperature changes outside production range

✓ Enhance production processes by reducing human error

✓ Utilize a dedicated mobile application for continuous asset access

✓ Generate detailed temperature datasheets and reports access historical database

✓ Analyze production process parameters to predict potential issues

Results

✓ Enhanced product quality

✓ Operational efficiency and predictive analytics-driven optimization

✓ Compliance with regulatory standards ensured and data-driven insights

✓ Increased throughput & waste reduction

✓ Operational efficiency and predictive analytics-driven optimization

✓ Compliance with regulatory standards ensured and data-driven insights

✓ Increased throughput & waste reduction