Compliance with the cold chain during the transport of pharmaceutical and food products is crucial. Breaks in the cold chain for heat-sensitive products can result in carrier liability. Temperature monitoring and control are therefore significant health and economic challenges. To address these challenges, a leading shipping and logistics company operating in Italy and across Europe has partnered with Ubiquicom and ELA Innovation.

They have implemented a comprehensive fleet management solution to track isothermal containers throughout the transport cycle. This solution covers the entire journey, from pick-up to final delivery, including transitions between branches where the isothermal boxes are within thousands of refrigerated containers across various Italian regions.

They have implemented a comprehensive fleet management solution to track isothermal containers throughout the transport cycle. This solution covers the entire journey, from pick-up to final delivery, including transitions between branches where the isothermal boxes are within thousands of refrigerated containers across various Italian regions.

Integrating ELA sensors into our cold chain IoT platform brings innovation to the market and guarantees product integrity to the customer from end to end, with clear indication and position of temperature anomalies in real time.

Davide Renzi

CTO UBIQUICOM

Compliance with the cold chain during the transport of pharmaceutical and food products is crucial. Breaks in the cold chain for heat-sensitive products can result in carrier liability. Temperature monitoring and control are therefore significant health and economic challenges. To address these challenges, a leading shipping and logistics company operating in Italy and across Europe has partnered with Ubiquicom and ELA Innovation.

They have implemented a comprehensive fleet management solution to track isothermal containers throughout the transport cycle. This solution covers the entire journey, from pick-up to final delivery, including transitions between branches where the isothermal boxes are within thousands of refrigerated containers across various Italian regions.

They have implemented a comprehensive fleet management solution to track isothermal containers throughout the transport cycle. This solution covers the entire journey, from pick-up to final delivery, including transitions between branches where the isothermal boxes are within thousands of refrigerated containers across various Italian regions.

Integrating ELA sensors into our cold chain IoT platform brings innovation to the market and guarantees product integrity to the customer from end to end, with clear indication and position of temperature anomalies in real time.

Davide Renzi

CTO UBIQUICOM

The project's participants

- The client's needs

- Technical Operation

- Results

The client's needs

✓To monitor in real time position and temperature of thousands of isothermal containers for pharmaceuticals and food during shipment.

✓To ensure efficient and sustainable cargo storage.

✓To maintain an accurate and reliable record of temperature variations.

✓To ensure high service availability at all data flow stages.

✓To ensure product quality.

✓To ensure efficient and sustainable cargo storage.

✓To maintain an accurate and reliable record of temperature variations.

✓To ensure high service availability at all data flow stages.

✓To ensure product quality.

Technical Operation

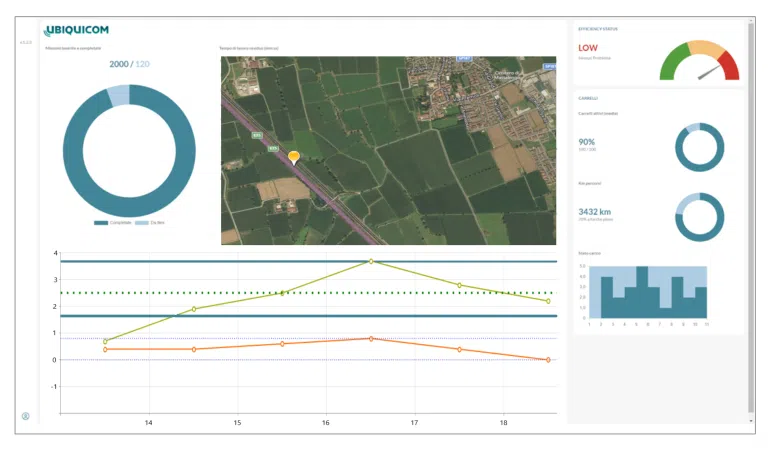

From a technical point of view, each isothermal container is equipped with ELA Innovation Blue PUCK T EN12830 temperature sensors. These Bluetooth Low Energy and highly reliable sensors, provide high-precision temperature monitoring and long autonomy. The sensors continuously gather data on the container’s location and internal temperature. Each piece of data is linked to information on the refrigeration unit housing the container and its relative position. Location calculation uses GNSS technology for outdoor areas and BLE location systems or cellbased systems for indoor areas. Gateways mounted on vehicles, hubs, exchange zones, and refrigerated cells transmit sensor data to the UBIQUICOM software platform in real time. Multiple levels of temporary data storage ensure data continuity, preserving information during disconnections and delivering it to the platform once the connection is restored. The UBIQUICOM software platform integrates in real time data from various sources to accurately reconstruct the thermal curve of each load. End-user can visualize temperature history and location data as graphs and reports on this platform. Real-time alarms for out-of-threshold values are managed based on configured tolerances and limits. If the temperature exceeds preset limits, an alert is sent to the

driver’s smartphone.

driver’s smartphone.

Results

✓End-to-end temperature tracking in compliance with EN 12930 and ISO 27001

✓Real-time issues management to prevent product spoilage and address anomalies immediately

✓Correlation of transport operators and vehicles with location details and travel durations

✓Real-time issues management to prevent product spoilage and address anomalies immediately

✓Correlation of transport operators and vehicles with location details and travel durations

Equipment

- The benefits

- Results

The benefits

✓Permanent and real-time monitoring of the temperature of isothermal containers

✓Quick and easy installation of sensors and platform deployment

✓Reliability and high accuracy of datas

✓Quick and easy access to accurate reports and history

✓Quick and easy installation of sensors and platform deployment

✓Reliability and high accuracy of datas

✓Quick and easy access to accurate reports and history

Results

✓End-to-end temperature tracking in compliance with EN 12930 and ISO 27001

✓Real-time issues management to prevent product spoilage and address anomalies immediately

✓Correlation of transport operators and vehicles with location details and travel durations

✓Real-time issues management to prevent product spoilage and address anomalies immediately

✓Correlation of transport operators and vehicles with location details and travel durations